Maintaining an air purifier in a workshop is essential for clean air. It ensures your workspace stays healthy and safe.

Workshops can be dusty and filled with various particles. This environment can strain your air purifier. Regular maintenance keeps it running efficiently. You need to know the right steps to care for your device. Proper upkeep means better air quality and longer purifier life.

Ready to learn how? Let’s dive into the essential tips for maintaining your workshop air purifier. This guide will help you keep the air fresh and your purifier in top shape.

Choosing The Right Air Purifier

Maintaining an air purifier in a workshop starts with choosing the right one. The right air purifier ensures a clean, healthy environment. It also prolongs the life of your equipment. Let’s explore the different types and key features to help you make the best choice.

Types Of Air Purifiers

Several types of air purifiers are suitable for workshops:

- HEPA Air Purifiers: These use High-Efficiency Particulate Air (HEPA) filters. They capture small particles, including dust and allergens.

- Carbon Air Purifiers: These use activated carbon filters. They remove odors and harmful gases.

- UV Air Purifiers: These use ultraviolet light. They kill bacteria and viruses.

- Ionic Air Purifiers: These use ionization. They attract and remove particles from the air.

Key Features To Look For

When selecting an air purifier, consider the following features:

- Filter Type: Choose the filter type that suits your needs. HEPA for particles, carbon for gases, UV for germs.

- CADR Rating: Clean Air Delivery Rate (CADR) measures efficiency. Higher CADR means faster air purification.

- Noise Level: Check the noise level. A quieter unit ensures a pleasant working environment.

- Coverage Area: Ensure the purifier can cover your workshop’s size. Larger areas need more powerful units.

- Maintenance: Look for easy-to-replace filters. Consider the cost of replacement parts.

Here’s a quick comparison of different air purifiers:

| Type | Best For | Pros | Cons |

|---|---|---|---|

| HEPA | Particles | Effective, reliable | Can be noisy |

| Carbon | Gases, odors | Removes smells | Not for particles |

| UV | Germs | Kills bacteria | Requires regular bulb replacement |

| Ionic | Allergens | Low maintenance | Ozone production |

By understanding these types and features, you can choose the perfect air purifier for your workshop. This will ensure clean air and a healthy workspace.

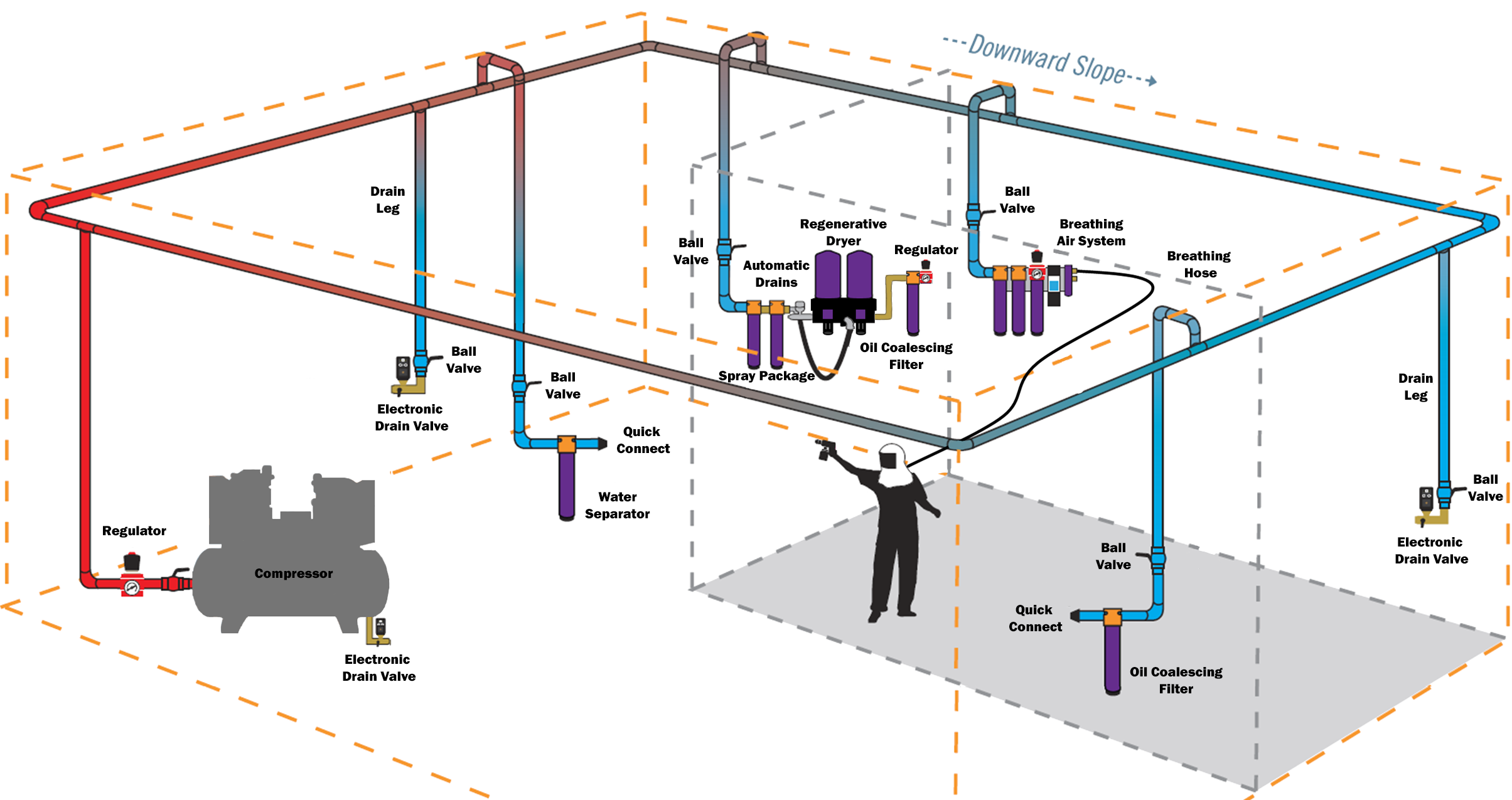

Credit: www.gosuburban.com

Proper Installation

Proper installation is crucial for the effective operation of an air purifier in a workshop. Ensuring your air purifier is installed correctly can make a big difference in air quality. This involves understanding where and how to place it.

Ideal Placement

Choose a central location in the workshop. The air purifier should be in a spot where it can cover the entire area. Avoid placing it near walls or furniture that can block airflow. Ensure there is enough space around the device for air to circulate freely.

Installation Tips

Read the manufacturer’s instructions carefully. Follow all guidelines to set up the purifier correctly. Place the device on a stable, flat surface. Ensure it is away from any sources of dust or pollutants. Check that all filters are securely in place before turning it on. Regularly inspect the device for any signs of wear or damage.

Regular Filter Replacement

Maintaining an air purifier in a workshop is essential. One of the key tasks is regular filter replacement. This ensures the air remains clean and free from harmful particles. It also helps the air purifier work efficiently, extending its lifespan.

Filter Types

Different air purifiers use various types of filters. The most common ones are HEPA filters, activated carbon filters, and pre-filters. Each type serves a specific purpose. HEPA filters trap tiny particles. Activated carbon filters remove odors and gases. Pre-filters capture large particles like dust and hair.

Replacement Schedule

Knowing the right time to replace filters is crucial. HEPA filters typically need replacement every 6 to 12 months. Activated carbon filters should be changed every 3 to 6 months. Pre-filters may require more frequent changes, about every month. Always check the manufacturer’s guidelines for your specific model.

Set reminders to stay on track with replacements. This small task can make a big difference. It keeps the workshop air clean and safe. It also helps the air purifier run smoothly, saving you money on repairs.

Cleaning The Unit

Maintaining an air purifier in a workshop is essential for its efficiency. Cleaning the unit regularly ensures it runs smoothly and lasts longer. Dust and debris can clog the unit, reducing its effectiveness. Let’s dive into the steps for cleaning both the external and internal parts of the unit.

External Cleaning

Start with the exterior of the air purifier. Unplug the unit for safety. Use a soft, damp cloth to wipe down the surface. Focus on removing dust and grime. Pay attention to the vents. A vacuum cleaner with a brush attachment can help. Clean the control panel gently. Avoid using harsh chemicals. They can damage the surface.

Internal Cleaning

Internal cleaning requires more attention. Remove the filter carefully. Consult the user manual if unsure. Use a vacuum cleaner to remove dust from the filter. Some filters are washable. Rinse them with water and let them dry completely. Clean the interior components with a soft brush. Ensure no dust remains inside. Reassemble the unit once everything is clean and dry. Regular cleaning ensures optimal performance.

Monitoring Air Quality

Keeping a close eye on air quality is essential in a workshop. It ensures a safe and healthy environment for everyone. An air purifier can help achieve this. But, you must monitor and adjust its settings regularly. This ensures it works well and meets your needs.

Using Air Quality Sensors

Air quality sensors are vital for checking pollution levels. They provide real-time data on the air quality. Many modern air purifiers come with built-in sensors.

- These sensors detect pollutants such as dust, smoke, and chemicals.

- The purifier adjusts its settings based on sensor readings.

- You can also use external sensors for more accurate data.

Placing sensors in different parts of the workshop ensures better monitoring. This helps in detecting varying pollution levels throughout the space.

Adjusting Settings

Adjusting the air purifier settings is crucial for effective air quality control. Most purifiers offer different modes and speeds.

- Auto Mode: Adjusts the fan speed based on sensor data.

- Manual Mode: Allows you to set the fan speed and other settings.

- Sleep Mode: Reduces noise and energy use at night.

Regularly adjusting these settings helps maintain good air quality. It also ensures the purifier runs efficiently.

| Mode | Usage |

|---|---|

| Auto Mode | For dynamic adjustment based on air quality |

| Manual Mode | For custom settings and specific needs |

| Sleep Mode | For quiet and energy-efficient operation |

Use the air purifier’s app or control panel to make these adjustments. Regular checks and adjustments ensure optimal performance.

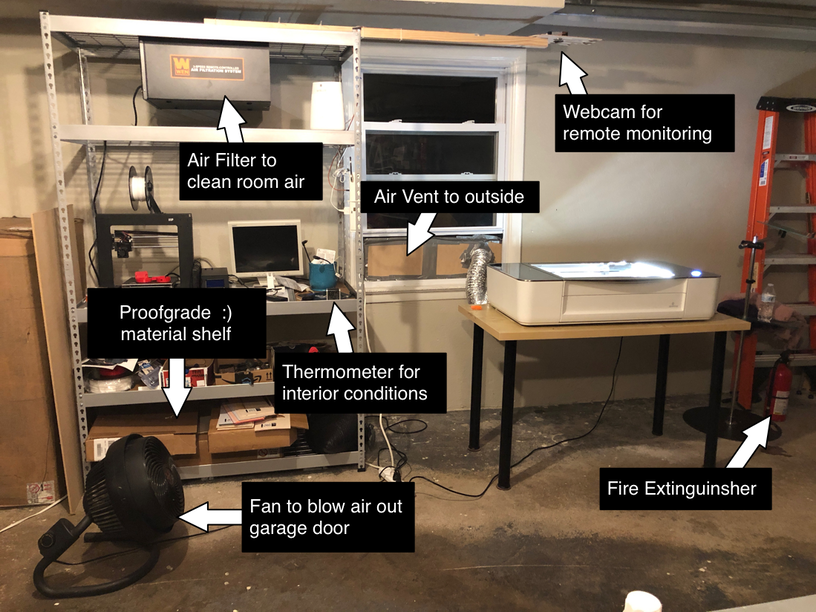

Credit: community.glowforge.com

Routine Maintenance

Routine maintenance is key to ensuring your air purifier works efficiently. Regular checks help catch problems early and extend the machine’s life. This section will guide you through the essential steps.

Inspecting For Damage

First, check the air purifier for any visible damage. Look for cracks in the housing or loose parts. Inspect the power cord and plug for wear and tear. Make sure the unit is stable and does not wobble. If you find any issues, address them immediately to prevent further damage.

Lubrication And Parts

Lubrication is crucial for the moving parts of your air purifier. Check the manufacturer’s manual for guidance. Apply the recommended type of lubricant to the motor and fan blades. This helps reduce friction and noise. Next, examine the filters and replace them if necessary. Clean the pre-filters regularly to ensure optimal performance.

Also, inspect the belts and screws. Tighten any loose screws and replace worn-out belts. Keeping these parts in good condition ensures your air purifier runs smoothly.

Handling Common Issues

Maintaining an air purifier in a workshop ensures clean air and a healthy environment. But sometimes, common issues can arise. Understanding these issues can help keep the air purifier in top shape. This section will guide you through handling these common problems.

Troubleshooting Guide

When an air purifier stops working correctly, a troubleshooting guide can be handy. Here are some common issues and solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Air purifier not turning on | Power cord unplugged or damaged | Check the power cord and plug it in securely. Replace if damaged. |

| Reduced airflow | Clogged filter | Clean or replace the filter as per the manufacturer’s instructions. |

| Unpleasant odors | Accumulated particles in the filter | Replace the filter to eliminate odors. |

| Loud noise | Loose components | Tighten any loose parts. Ensure all components are secure. |

When To Call A Professional

Sometimes, issues with air purifiers require expert attention. Knowing when to call a professional can save time and prevent further damage.

- Persistent Issues: If the problem persists after troubleshooting, seek professional help.

- Complex Repairs: For complex repairs, it’s best to call an expert.

- Warranty Coverage: If your air purifier is under warranty, contact the manufacturer for service.

Regular maintenance and timely troubleshooting keep your air purifier running efficiently. When in doubt, always consult a professional to ensure the longevity of your device.

Safety Precautions

Ensuring safety while maintaining an air purifier in a workshop is crucial. Proper handling and avoiding electrical hazards are vital to keep both the device and users safe.

Proper Handling

Always turn off and unplug the air purifier before maintenance. This ensures you don’t accidentally start the device. Handle the purifier with dry hands to avoid slipping. Place the purifier on a stable surface to prevent falls or damage. Use the manufacturer’s guide for specific handling instructions.

Avoiding Electrical Hazards

Inspect the power cord regularly for any signs of wear or damage. Replace damaged cords immediately to prevent electrical shocks. Avoid using extension cords, as they can overload circuits. Ensure the air purifier is plugged into a grounded outlet. Keep the purifier away from water sources to reduce the risk of electrical hazards.

Credit: www.shophacks.com

Frequently Asked Questions

How Often Should I Clean My Air Purifier?

Clean your air purifier every 2-4 weeks. This helps maintain optimal performance and air quality. Check the manufacturer’s guidelines for specific cleaning intervals.

What Tools Do I Need To Maintain My Air Purifier?

You need a soft cloth, a vacuum cleaner with a brush attachment, and mild soap. These tools help you clean the unit effectively without causing damage.

Can I Use Water To Clean Air Purifier Filters?

Yes, you can rinse washable filters with water. Ensure they are completely dry before reinstalling. Do not use water on non-washable filters.

How Do I Know When To Replace The Filter?

Replace the filter when the indicator light turns on. Refer to the user manual for specific replacement intervals. Regularly check the filter’s condition.

Conclusion

Maintaining an air purifier in a workshop is crucial. Clean filters regularly. Check for dust buildup. Replace filters as needed. Keep the purifier in a well-ventilated area. Follow the manufacturer’s instructions. Regular maintenance ensures better air quality. Your workshop will stay cleaner.

This improves health and productivity. A well-maintained purifier lasts longer. It’s a simple, effective task. Enjoy a cleaner, healthier workshop environment.

Rakib Sarwar is a Registered Pharmacist and a reputed health and wellness blogger. He has a great interest in Air purifiers.